Innovative Solutions Shaping the Future of Industrial Fabrication

Introduction to Innovative Solutions in Industrial Fabrication

Industrial fabrication has always been at the forefront of technological advancement, driving efficiency and innovation in manufacturing processes. Today, the industry is undergoing a significant transformation, thanks to groundbreaking solutions that are reshaping how we approach fabrication. From automation to advanced materials, the future of industrial fabrication looks promising and exciting.

Automation: Revolutionizing Production Lines

Automation is no longer just a buzzword; it is a reality that is transforming production lines across the globe. With the integration of robotics and AI, companies can now ensure precision, reduce human error, and significantly cut down on production time. This shift not only increases productivity but also enhances safety by minimizing the need for human intervention in hazardous environments.

One of the most significant advantages of automation is its ability to operate continuously, leading to higher output. Moreover, the use of smart sensors and IoT devices allows for real-time monitoring and optimization of production processes, ensuring that any issues are addressed promptly.

Advanced Materials: Enhancing Durability and Efficiency

The development of advanced materials is another area where innovation is making a significant impact. New composites and alloys are being engineered to withstand extreme conditions, offering enhanced durability and performance. These materials not only improve the quality of the finished products but also contribute to sustainability by reducing waste and energy consumption.

For instance, the use of lightweight yet strong materials in automotive and aerospace industries is leading to more fuel-efficient vehicles and aircraft. This trend towards sustainability is a driving force behind the research and development of new materials.

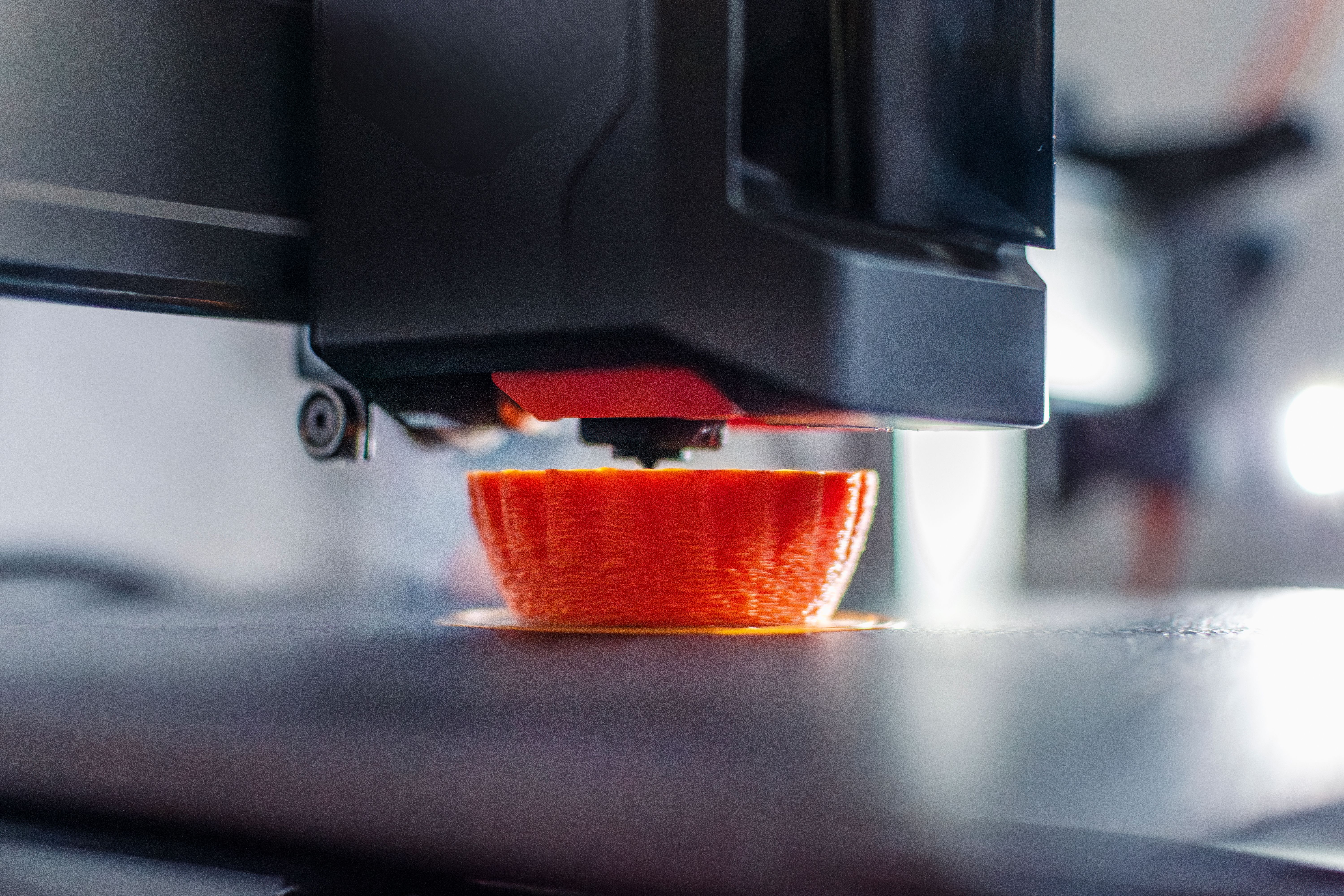

3D Printing: A Game Changer in Fabrication

3D printing, or additive manufacturing, is revolutionizing the way we think about fabrication. This technology allows for the creation of complex geometries and custom parts with unprecedented precision. It enables rapid prototyping, reducing the time from design to production and allowing for greater flexibility in manufacturing.

Industries ranging from healthcare to aerospace are adopting 3D printing to produce everything from intricate medical implants to lightweight aircraft components. The ability to produce on-demand reduces inventory costs and minimizes waste, aligning with the growing emphasis on sustainability in industrial practices.

Data-Driven Approaches: Optimizing Fabrication Processes

The role of data in industrial fabrication cannot be overstated. By leveraging big data and analytics, companies can gain valuable insights into their production processes. These insights enable them to optimize operations, predict maintenance needs, and improve overall efficiency.

Predictive maintenance, for example, uses data to forecast when machinery is likely to fail, allowing for timely interventions and reducing downtime. This proactive approach not only saves costs but also extends the lifespan of equipment.

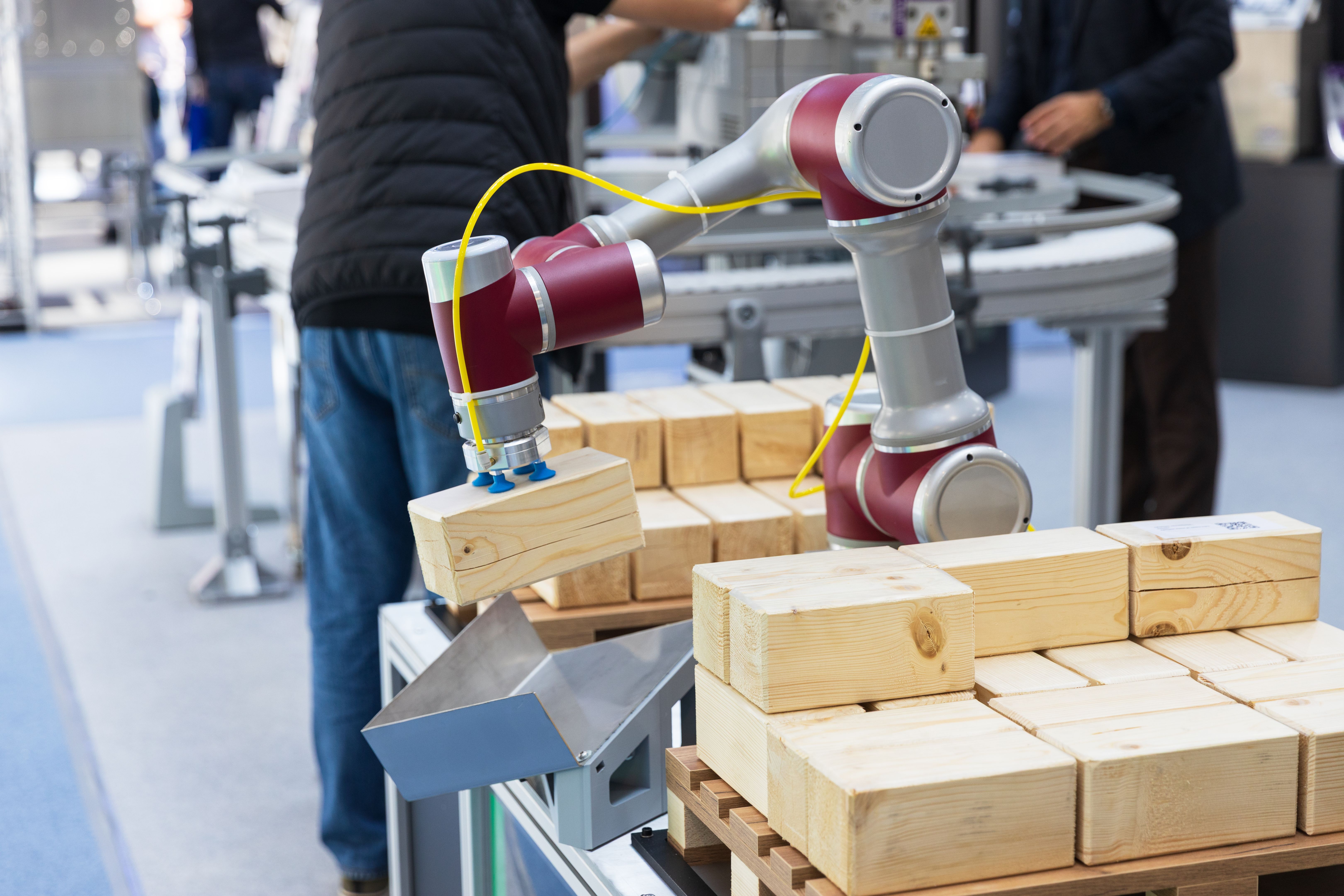

Collaborative Robotics: Enhancing Human-Machine Interaction

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety. Unlike traditional robots, cobots are equipped with sensors and safety features that allow them to operate in close proximity to human workers.

This collaboration between humans and machines allows for a more flexible and efficient production environment. Cobots can handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex and creative aspects of manufacturing.

Conclusion: Embracing the Future of Fabrication

The future of industrial fabrication is bright, with innovative solutions driving significant advancements in the field. As companies continue to adopt these technologies, we can expect to see improvements in efficiency, safety, and sustainability across the board.

By embracing these cutting-edge solutions, industries can not only meet the demands of today but also prepare for the challenges of tomorrow. As we move forward, the integration of these innovations will continue to shape the landscape of industrial fabrication, leading to a more efficient and sustainable future.